OEM Manufacturer Pipe Induction Heating Furnace - Induction Melting Furnace – Rongtai

OEM Manufacturer Pipe Induction Heating Furnace - Induction Melting Furnace – Rongtai Detail:

Power Supply:

RT Multi-Output Power Supply Units can power two or more furnaces simultaneously for greater production with a minimum investment for each ton of metal being poured. Some of the many advantages include:

- A single power unit with the batch production capacity of multiple units

- Uninterrupted melting and precise temperature control for holding or superheating

- Ability to simultaneously preheat, sinter, melt and/or ultra low power hold in multiple furnaces

- Increased alloy flexibility

- Equipment power utilization levels approaching 100 percent

- Increase metal production without increasing power demand levels

- Separate sets of controls for each furnace

- Ability to efficiently match production to varying levels of metal demand

- Only one set of power and water connections needed, greatly reducing installation, operation and maintenance costs

- The ability to direct full rated power to one furnace while fully isolating another during maintenance

- The latest generation of digital computing technology, microcontroller program control.

- Low start frequency, ultra low furnace lining stoving power.

- The rectification is full open, the power factor is high, and the upper harmonics are small.

- Using the latest generation of parallel resonance technology, greatly reducing the power consumption index

- Electrical safety design standards in line with international and domestic standards

- More sophisticated and intelligent protection function

Furnace:

Lower Installation Costs: These furnaces are ideal for installations where overhead clearances impose height restrictions. They also require shallower pit excavation for lower installation costs.

Lower scrap costs: This feature provides a crucible opening that is 20 to 30 percent larger in diameter than a standard profile furnace of the same metal capacity which allows foundries to use larger, bulkier (and often less expensive) charge materials. For foundries with larger returns and long risers, particularly common in ductile iron shops, the larger furnace opening reduces cutoff labor and related scrap processing costs.

Better access to slag: The larger furnace opening also provides better access for the removal of slag or dross buildup on the furnace walls. This is particularly important in furnaces used for nonferrous melting where a melt deck worker must be able to reach to the bottom of the furnace with a refractory scraper.

Expanded function: It can be installed with backslagging device, furnace lining push-out system and furnace pit protection device to improve the convenience and safety of melting operation; it can also be equipped with various fume collecting rings and hoods to help you comply with the strictest air pollution requirements, such as MACT standards.

Casting automation: Weighing frame can be equipped to weigh the weight of molten metal in real time, and transfer various production data to the factory production process execution system (MES) for intelligent factory management.

| Power Supply: | |

| Power Ranges | 180KW-10,000KW |

| Contact Rongtai for Custom Solutions | |

| Standard Features | Precise and Responsive Digital Controls |

| Digital Control Board with Fiber-optic Clear Signal Processing | |

| Touch-screen Display for Control and Data Entry | |

| Built-in Ground and Leak Detector System | |

| 6、12 or 24 Pulse Line Power Rectifier System | |

| Informative Diagnostics | |

| Power Control Adjustable at all Power Levels, Manual or Automatic | |

| Optional Features | System Status Text Messaging |

| Melting-Cloud Control Systems | |

| Factory Tested | Critical Components |

| Furnace: | |

| Capacities | 250 kg—30 Tons |

| Contact Rongtai for Custom Solutions | |

| Standard Features | Large Access Panels |

| Steel Shell Protection | |

| Insulated Covers | |

| Higher Freeboard | |

| Ground Leak Detection | |

| Magnetic Yoke | |

| Optional Features | Load Cells |

| Back-tilting, Nose-tilting and Pre-tilting Systems | |

| Integrated Fume Ring | |

| Fume Collectors and Hoods | |

| Safety Pit Guards | |

| Weigh Frames | |

| Lining Push-out System | |

| Additional Wide-bodied Design Features | Large Bath Diameter |

| Lower Stance | |

| Shallow Pit Depth | |

| Factory Tested | Critical Components |

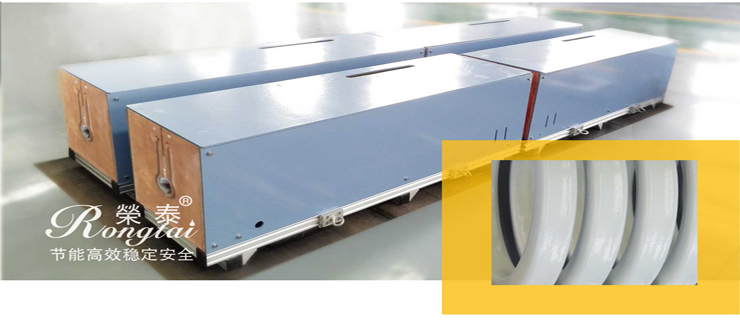

Product detail pictures:

Related Product Guide:

Global DC Electronic Load Market 2019 Industry Insights Market Players | Industrial High Temperature Aluminum Electric Furnace

$500 million expansion of Baytown steel mill announced | Steel Bar Forging Furnace Machine

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for OEM Manufacturer Pipe Induction Heating Furnace - Induction Melting Furnace – Rongtai , The product will supply to all over the world, such as: Czech, Doha, Israel, Insisting over the high-quality generation line management and prospects guide provider, we've made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!